The process of making alcoholic beverages from primary grains is fundamentally a four step process. First, the grains have to be cooked and the starches in them have to be converted to sugars in a process known as Mashing. Secondly, the sugars have to be acted on by yeast cells which convert those sugars to ethyl alcohol in a process called Fermentation. The resulting liquid then has to be processed to separate and purify the alcohol – this is Distillation. Finally, the alcohol must be Proofed (mixed with water to obtain a certain alcohol content per volume) and bottled. Each of these steps requires special care and control to achieve the optimal (that is, flavorful) result.

Good beginnings and careful process control leads to exceptional results

1. Mashing

In distilling, mashing is the process of combining and heating a mix of water and ground grains – typically malted barley (grains that have been allowed to sprout and then stopped from further growth) with supplementary grains (known as the “grain bill”) such as corn, sorghum, rye, or wheat. In Capstone’s case, we use rice as our supplementary grain for flavor and smoothness of the final product. This process makes a “grain porridge” that gelatinizes the starches and breaks them down into sugars that the yeast in the next step – fermentation -will consume.

2. Fermentation

In order for fermentation to occur, two things are needed: a raw material in liquid form that contains sugar, followed by the addition of yeast. Yeast is a living organism that feeds on sugar; the byproduct of this consumption is alcohol and carbon dioxide (CO2) plus the congeners – the elements which create the flavors of each drink.

The simple formula for fermentation is:

YEAST + SUGAR = ALCOHOL + C02

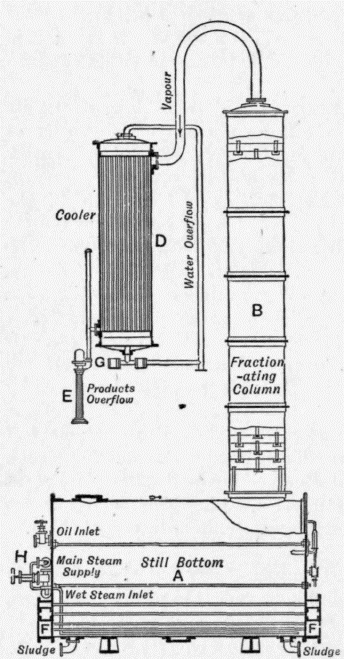

3. Distillation

In distillation the grain particles, water, alcohol, and congeners are heated. The alcohol vaporizes first, leaving the grain particles, water and some of the congeners in the boiling pot. The vaporized alcohol is then cooled or condensed forming clear drops of distilled spirits. The first vapor to condense is called the “Foreshot” and is typically discarded because it can contain harmful compounds and off-flavors, such as acetone and aldehyde volatiles. The “Tails” are the vapors at the end of the distillation characterized by a low alcohol content and high concentration of unwanted compounds such as fusel oils, which can negatively impact the taste and aroma of the final product and are usually discarded.

4. Proofing

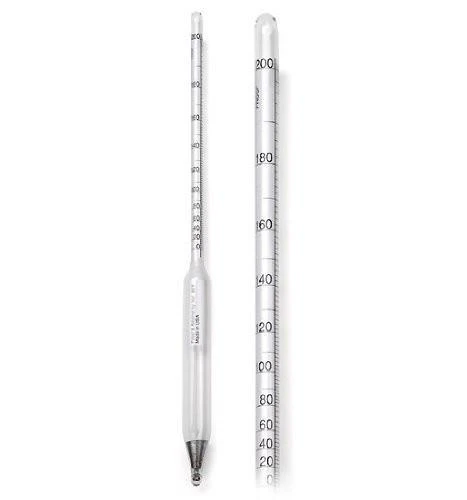

Proofing is the act of determining the alcoholic strength of spirits. “Proofing down” is the act of adding water to spirits to reach a target alcoholic strength. Proof is a measure of the absolute alcohol content of a distilled liquor, which is a mixture of alcohol and water. The measurement is made by determining the specific gravity of the liquor; that is, the weight per unit volume of the liquid compared to that of water.

Some distillers sample their spirit at different proofs to find the one that best showcases its flavors and aromas. The higher the proof the less quickly aromas and flavors evaporate. The legal minimum proof for a straight liquor (no additives) is 80 proof or 40%ABV.

Distilled spirits plant proprietors must gauge their spirits to determine the quantity and proof of the spirits so they can calculate the taxes owed. The higher the proof the higher the tax.

The typical proof of alcohol varies by type of beverage, but here are some common ranges:

Brandy, gin, rum, tequila, vodka, and whiskey: Typically 80 proof (40% ABV)

Liqueurs: Typically 30–60 proof (15–30% ABV), but some are 80 proof (40% ABV)

Beer: Typically 4–7% ABV, but can range from 3–13% ABV